Expert Process Plant Design & Engineering Services for Seamless Operations

At Global Detailing Consultant, our team of experts in the piping design department offers comprehensive design and detail engineering services. We cater to a wide range of industries including oil and gas, refinery, petrochemical, chemical, offshore, power plant, utility, and pharmaceutical sectors. With our expertise and experience in these industries, we are well-equipped to handle the unique challenges and requirements of each project. Trust us to deliver top-quality services that meet the highest standards of precision and efficiency.

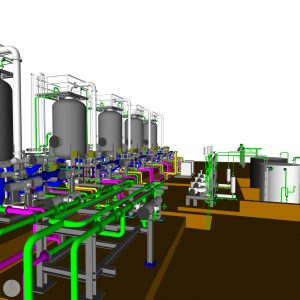

We are delighted to offer our Process Plant Design & Engineering Services, providing comprehensive solutions for various industries. Our experienced team specializes in designing and engineering process plants, ensuring optimal efficiency, safety, and compliance with industry standards.

Our team of highly skilled engineers possess a wide range of expertise in various activities related to design review, contractor document and drawing review, as well as project coordination. They utilize an array of advanced software tools such as SmartPlant 3D, PDS, PDMS, CADWorx, AutoPlant 3D, AutoCAD, MicroStation, SmartPlant Review, NavisWorks, Vantage Review, CAESAR II, Pelican Forge – Support Modeler and MDS – Support Modeler to support their work. Rest assured that our engineers are equipped with the necessary skills and tools to successfully meet the demands of your project.

Piping Services:

- Piping material specifications

- 3D model project set-up

- Painting and insulation specification

- Site survey / tie-in sketches

- Single line structure drawings

- Piping studies

- Updating plot plans and unit plot plans

- Updating key plans

- Equipment modeling

- Nozzle orientation drawings

- Modeling of lines

- Interface with other disciplines

- Stress analysis

- Pipe supports

- Clash checking

- Model reviews

- Isometrics

- Piping general arrangement drawings

- Piping material take-offs

- Support material take-off

- Insulation and painting take-off

- Requisitions

- Tracing / jacketing

Mechanical

Our esteemed mechanical design department, Global Detailing Consultant, excels in providing top-notch design and detail engineering services for a range of industries including oil and gas, refinery, petrochemical, chemical, offshore, power plant, utility, and pharmaceutical. Whether it’s static or rotating equipment, packages or HVAC systems – we’ve got you covered. Trust us to deliver exceptional solutions tailored to your specific needs.

Throughout our experience, we have successfully handled a wide range of equipment, both static and rotating. Our expertise covers pressure vessels, shell and tube heat exchangers, towers, reactors, condensers, evaporators, as well as pumps and compressors. We are well-versed in international codes and standards such as ASME Section VIII Div-1 and Div-2, BS PD5500, EN13445, TEMA, API. Additionally, we excel in wind and seismic analysis conforming to IBC (International Building Code), UBC (Uniform Building Code), ASCE (American Society of Civil Engineers), NBC (National Building Code). When it comes to detail engineering documents needed for your project‘s success – be it specifications or drawings – you can rely on us to deliver with utmost precision.

- Mechanical data sheet preparation

- Preparation of general arrangement drawings

- Technical clarifications during contract finalization

- Providing civil loading details for equipment

- Final mechanical design verification of compliance with international codes

- Strength calculations by using in-house programs / PV ELITE / COMPRESS

- Detailed manufacturing drawings

- Preparation of bill of materials

- Specifications for raw materials

- Purchase specifications for brought out items

- HVAC

- Heat load calculations

- Design / selection of equipment

- Design of ducts according to SMACNA, DW standards

- General arrangement drawings

- Duct fabrication drawings

- Duct support drawings

- Material take off

Our highly skilled engineers possess a wide range of expertise in various related activities. They excel in tasks such as reviewing design analysis, examining contractor design documents and drawings, and coordinating projects seamlessly. Their proficiency guarantees the smooth execution of your projects while maintaining the highest standards of quality.

Our team of experts is well-versed in utilizing a wide range of supporting software tools, such as PV Elite, COMPRESS, TANK, AutoCAD, and MicroStation. With their extensive experience and proficiency in these programs, they can efficiently tackle any project and deliver exceptional results. You can rely on their expertise to ensure optimal utilization of these software solutions for your specific needs.

Civil and Structural

At Global Detailing Consultant, our highly skilled civil and structural department specializes in providing top-notch design and detail engineering services for a wide range of industries. From process plants to power plants, refineries to oil and gas plants, air separation plants to petrochemical industries, fertilizer plants to steel plants, cement plants to infrastructure facilities – we cover it all. Our dedicated team has extensive experience in preparing design calculations, detailed drawings, bar bending schedules, and bill of materials that adhere strictly to international standards. We take pride in delivering comprehensive and reliable solutions for every project we undertake.

- Preparation of design basis

- Preparation of project specification

- Reinforced concrete framed structures

- Pile and conventional foundations

- Equipment and machinery foundations

- Concrete storage silos and large diameter storage tank foundations

- Retaining, dyke, and boundary walls

- Cable and pipe trenches and tunnels

- Roads, pavement, grading plans, and drainage systems

- Gates, compound walls, and fencing

Global Detailing Consultant has a proven track record of delivering design calculations and detailed structural drawings that adhere to international standards. Our expertise extends to fabrication drawings and preparing accurate bill of materials. With our commitment to quality, you can trust that your project will be executed with precision and in line with global best practices.

- Preparation of design basis

- Preparation of project specification

- Steel framed buildings and superstructures

- Pipe and cable rack structures, conveyor galleries, trestles, stack supporting structures, and platforms

- Large diameter / size storage sheds

- Turbine houses and workshop buildings

- Switch yards and transmission line towers

Our team of engineers brings a wealth of expertise to various activities that are crucial for project success. From diligently reviewing design criteria to meticulously examining contractor design documents and drawings, we ensure that every aspect is thoroughly evaluated. Additionally, our engineers excel in project coordination, guaranteeing seamless collaboration among stakeholders for efficient execution.

Our team is well-versed in a multitude of software applications that support our work, such as STAAD. Pro, STAADRAM, SACS, AutoCAD, MicroStation,, MAT 3D, Foundation 3D, InRoads, Architectural Desktop, BOCAD and Intergraph’s PDS FrameWorks Plus. With expertise in these tools and more, we ensure our modeling processes are efficient and accurate.

Electrical

Global Detailing Consultant‘s electrical department offers a wide range of design engineering services for various industries. Our team specializes in process plants, power plants, refineries, oil and gas plants, air separation plants, petrochemical industries, fertilizer plants, and steel plants. When it comes to detail engineering documents and tasks, we’ve got you covered. Our expertise includes providing comprehensive solutions such as:

- Preparation of design basis

- Preparation of project specification

- Load flow studies

- Selection of HV / LV switchgear, motor control centers

- Selection of AC / DC UPS

- Selection of power / distribution transformers

- Designing supply change over schemes for incomers and outgoing feeder control schemes

- Selection of feeder / motor / transformer protection relays

- Switchyard / transformer layouts

- Switchgear / MCC room layout

- Battery room layouts

- Cable tray / trench layouts

- Earthing layouts

- Cable routing layouts

- Lighting (indoor / outdoor) layouts

- Lightning protection layouts

- Power and control cable schedules

- SCADA I / O list

- Interface activities with civil / machinery / instrumentation

- Coordination with civil for floor openings, electrical equipment foundation, and plants

- Electrical data input for packaged equipment

- Requisition / specifications for HV / LV switchgear, motor control centre, MV / LV motors, power / distribution transformers, lighting / small power distribution boards, AC / DC UPS, lighting fixtures, power / control cables, cable trays, earthing materials, etc.

- Bill of quantities for bulk materials

- Standard installation drawings for power system, earthing system, lighting system and cable tray / ladders.

- Review vendor bids and issue technical bid analysis

- Review vendor drawings and issue approvals for manufacturing

- Attend SAFOP / HAZOP meetings

- Construction Scope of Work and responses to bidder’s technical queries

- As-built project drawings / documentation

Rest assured that our team of highly skilled engineers possesses expertise in a wide range of activities closely tied to project success. These include conducting thorough reviews of design criteria, scrutinizing contractor design documents and drawings, and efficiently coordinating various aspects of your project. With their proficiency and dedication, you can trust our engineers to deliver exceptional results in every aspect of your endeavor.

Our team has a wealth of experience in utilizing a range of software tools to support our work, including ETAP, SmartPlant Electrical, AutoCAD, MicroStation, DIALux, and Chalmlite. Our proficiency with these programs allows us to deliver top-notch results efficiently and effectively.

Instrumentation

Global Detailing Consultant’s instrumentation department is here to provide top-notch design and detail engineering services for a wide range of industries. From process plants and power plants to refineries, petrochemical facilities, oil and gas plants, air separation plants, fertilizer plants, steel plants, and cement plants – we’ve got you covered. Our team is well-versed in handling typical detail engineering documents and tasks that are essential for the smooth operation of these industries. We’re dedicated to delivering exceptional results that meet your specific needs.

- Preparation of design basis

- Preparation of project specification

- Preparation of control philosophy

- Preparation of detailed execution drawings

- Preparation of instrument index

- Preparation of instrument elevation plan

- Preparation of interlock logic diagrams

- Preparation of cable tray / cable trench layouts

- Preparation of junction box termination drawings

- Preparation of instrument hook up drawings

- Preparation of cable schedules

- Preparation of fire and gas drawings

- Preparation of cause and effect drawings

- Preparation of requisition and specifications for instruments

- Technical bid evaluation

- Review of vendor package systems

- Sizing of control valves, orifice plates, and relief valves

- Preparation of bill of materials

- Preparation of interface drawings for DCS, PLC, SCADA and MCC

- Attending SAFOP / HAZOP meetings

- Preparation of earthing layouts for system and field

- Preparation of scope of work for construction activities

- Preparation of FAT and SAT procedures

- Preparation of as -built drawings and documentation

Rest assured that our team of engineers is well-versed in a range of activities crucial to project success. This includes conducting thorough reviews of design criteria, contractor design documents, and drawings. Additionally, they excel at effective project coordination. Furthermore, our engineers are highly experienced in utilizing various supporting software tools. They are proficient users of SmartPlant Instrumentation (INtools), InstruCalc, MicroStation, and AutoCAD. With their expertise and advanced software skills, you can trust them to deliver outstanding results for your project.

Process

Global Detailing Consultant’s process department is dedicated to providing exceptional detail engineering services across a wide range of industries including process plants, power plants, refineries, petrochemical facilities, oil and gas plants, air separation plants, fertilizer plants, steel plants, and cement plants. Our team handles various detail engineering documents and tasks with utmost precision and expertise. From designing equipment layouts to optimizing process flows, we ensure every aspect of your project is meticulously addressed. Trust us to deliver the highest quality results for your engineering needs.

- Development of P&ID’s based on FEED

- Preparation of P&ID’s for utilities

- Sizing calculations

- Hydraulic calculations

- Performing insulation and heat tracing calculations

- Preparation of line list, equipment list, valve list, etc.

- Preparation of plant operation and maintenance manual

Our services encompass the entire process plant lifecycle, from conceptual design and feasibility studies to detailed engineering and construction support. We have expertise in a wide range of industries, including oil and gas, petrochemical, chemical, pharmaceutical, food and beverage, and many more.

Our Process Plant Design & Engineering Services include:

Conceptual Design: We work closely with clients to understand their requirements, goals, and constraints. Our team develops conceptual designs that outline the overall layout, process flow, equipment selection, and preliminary cost estimates.

Feasibility Studies: We conduct thorough feasibility studies to assess the technical and economic viability of process plant projects. Our studies evaluate factors such as resource availability, market demand, environmental impact, and regulatory compliance.

Process Engineering: Our team of process engineers designs and optimizes the various unit operations and processes within the plant. We utilize advanced simulation and modeling tools to analyze process performance, energy consumption, and material balances.

Equipment Selection and Sizing: We assist in selecting the appropriate equipment for each process, considering factors such as capacity, efficiency, reliability, and compatibility with the process conditions. We also size equipment to ensure optimal performance and safety.

Piping and Instrumentation Diagrams (P&IDs): We develop detailed P&IDs that outline the process flow, equipment, instrumentation, and control systems. Our P&IDs serve as a crucial reference for design, construction, and operation.

Plant Layout and 3D Modeling: We create detailed plant layouts and 3D models, optimizing space utilization, equipment accessibility, and safety. Our 3D models enable visualization of the plant, facilitating clash detection and coordination among various disciplines.

Mechanical and Structural Engineering: Our team provides mechanical and structural engineering services, ensuring the integrity and safety of equipment and structures. We design foundations, supports, platforms, and other structural elements, considering factors such as load capacity, seismic requirements, and durability.

Electrical and Instrumentation Engineering: We offer electrical and instrumentation engineering services, designing power distribution systems, control systems, and instrumentation layouts. We ensure compliance with relevant codes and standards while optimizing energy efficiency and system reliability.

Procurement Assistance: We provide support during the procurement phase, including technical bid evaluation, vendor coordination, and equipment inspection.

Construction Support: We offer construction support services, including site supervision, project management, and quality control. Our team ensures that the construction phase adheres to the design specifications and industry best practices.

By choosing our Process Plant Design & Engineering Services, you can expect a collaborative approach, attention to detail, and a commitment to delivering high-quality solutions that meet your project’s specific requirements.

One thought on “Process Plant design & Engineering Services Guide”