Importance of Steel Structural Detailing in Modern Construction Marvels – Global Detailing Consultant

Steel structural detailing is incredibly important in the construction industry, and I’ll tell you why without sugarcoating it. This meticulous process is the backbone of any steel-based building project, and getting it wrong can lead to absolute disaster. We’re talking about the nitty-gritty details that make sure a structure doesn’t come crashing down on people’s heads. Think about it – every bolt, every weld, every connection point needs to be spot-on. There’s no room for “close enough” when you’re dealing with tons of steel suspended above the ground.

Structural detailers are the unsung heroes who translate architects’ grand visions into practical, buildable plans. They’re the ones who ensure that when the steel fabricators start cutting and shaping, everything fits together like a giant, very expensive puzzle. And let’s not forget about the financial side. Mistakes in structural detailing can cost a fortune to fix, especially if they’re not caught until the construction phase. It’s not just about safety; it’s about keeping projects on time and on budget. In this industry, precision isn’t a luxury – it’s a necessity.

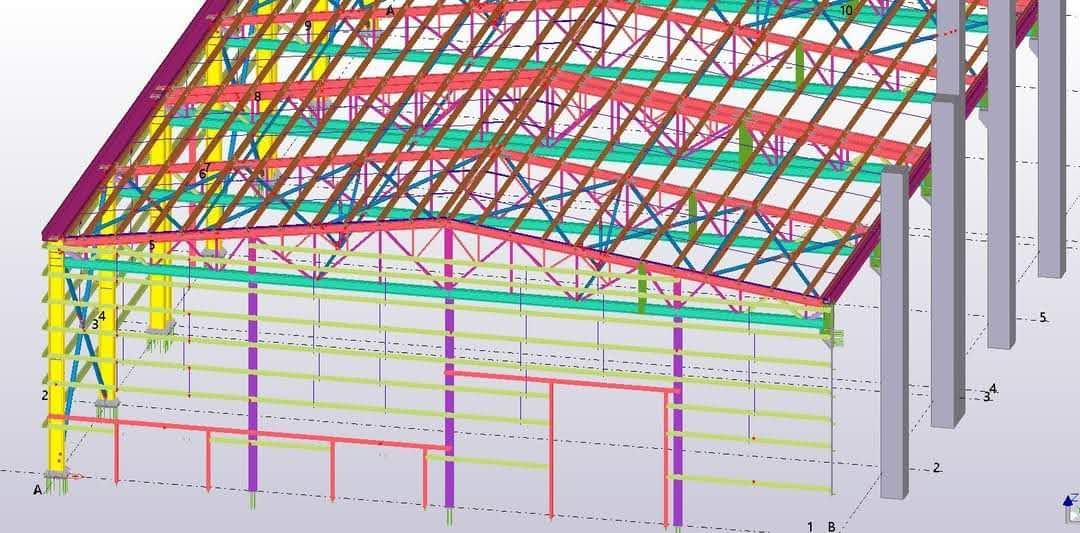

Structural Steel Detailing Services are essentially the unsung heroes of modern construction, acting as the architects’ meticulous instructions for steel construction projects. Picture this: you’re tasked with assembling a colossal metal puzzle, but instead of a table top model, it’s a towering skyscraper or a sprawling bridge. That’s where these services come in clutch. These detailed plans ensure that every single steel component – from the tiniest bolt to the most massive beam – is crafted and assembled with pinpoint accuracy. That’s why these services are so crucial. They’re the safety net, the guardian angels, and the quality control all rolled into one. They make sure the final structure isn’t just standing tall and proud, but that it’s also tough as nails, safer than a bubble-wrapped kitten, and matches the architect’s vision down to the last millimetre. So next time you’re gawking at a skyscraper or cruising over a bridge, spare a thought for the unsung structural steel detailing heroes.

Precision and Accuracy:

Steel detailing is a game-changer when it comes to getting things right the first time. It’s like having a super-detailed blueprint for every single piece of steel in your project. This meticulous approach ensures that every component, from the tiniest bolt to the largest beam, fits together like a dream. We’re talking about millimeter-level precision here, folks. By nailing down these details in advance, you’re basically giving yourself a get-out-of-jail-free card when it comes to those pesky on-site adjustments. You know the ones I’m talking about – the kind that eat up time, money, and patience faster than you can say “change order.” With proper steel detailing, those costly surprises become about as rare as a unicorn sighting. Let’s face it, nobody wants to be that person on the construction site playing an impromptu game of “make it fit” with a bunch of steel beams. Steel detailing eliminates that headache, ensuring everything slots into place smoother than a well-oiled machine.

Cost-Efficiency:

Accurate detailing is a game-changer when it comes to saving money and resources. Let’s face it, nobody likes to see their hard-earned cash go down the drain, and that’s exactly what happens when materials are wasted due to sloppy planning. By nailing down the details from the get-go, you’re essentially putting a leash on unnecessary spending. Think about it – when you’ve got a crystal-clear blueprint of what’s needed, you’re not just throwing stuff at the wall and seeing what sticks. You’re making calculated moves, using just the right amount of materials for the job. It’s like being a master chef who knows exactly how much of each ingredient to use – no more, no less. Plus, when you optimize your resources, you’re not just saving money; you’re being smart about how you use what you’ve got. It’s like squeezing every last drop out of a tube of toothpaste – you’re getting the most bang for your buck. In the long run, this approach can lead to significant savings, allowing you to allocate funds to other areas of your project or business. It’s a win-win situation that keeps your wallet happy and your project running smoothly.

Safety:

Proper detailing is absolutely crucial when it comes to the structural integrity of buildings. Let’s face it, nobody wants to be in a structure that’s falling apart or, worse, could collapse at any moment. Getting the details right isn’t just about making things look pretty; it’s about making sure the whole building stands up and doesn’t become a death trap. When architects and engineers pay close attention to every little detail, they’re essentially creating a foolproof blueprint for safety. It’s not just about following rules for the sake of it; these regulations are there for a reason. They’re the result of years of experience, often learned the hard way through past failures and accidents. Complying with these regulations isn’t optional; it’s a must. It’s the difference between a building that’s a ticking time bomb and one that can withstand the test of time, natural disasters, and whatever else life throws at it. So, when we talk about proper detailing, we’re really talking about the nuts and bolts of keeping people alive and well in the structures they inhabit every day. It’s serious business, and cutting corners here is simply not an option.

Time-Saving:

Detailed plans are a game-changer when it comes to keeping projects on track. They’re like a roadmap for your entire team, cutting through the chaos and confusion that can bog down construction work. With a solid plan in hand, fabricators can hit the ground running, knowing exactly what materials they need and how everything fits together. No more head-scratching or time-wasting guesswork on the job site. These plans also help construction crews work like a well-oiled machine. Everyone knows their role and what needs to be done, which means less time spent figuring things out on the fly. It’s like having a cheat sheet for the entire project, allowing workers to move from one task to the next with confidence and efficiency. This streamlined approach can shave days, even weeks, off project timelines, keeping clients happy and budgets in check. Let’s face it, time is money in this business, and detailed plans are like money in the bank when it comes to staying on schedule. They’re the secret weapon for avoiding those dreaded delays and cost overruns that can turn a promising project into a nightmare.

Communication:

Detailing serves as a crucial conduit for information flow, ensuring that everyone involved in the project – from architects and engineers to contractors and subcontractors – is on the same page. It’s like having a universal translator that speaks the language of construction. By providing clear, comprehensive information, detailing eliminates those frustrating “lost in translation” moments that can lead to costly mistakes or delays. It’s the difference between a game of telephone gone wrong and a well-orchestrated symphony of construction activities.

Quality Control:

Detailing acts as a vigilant watchdog throughout the construction process, keeping a keen eye on quality at every turn. It’s like having a strict but fair teacher looking over your shoulder, making sure you dot every ‘i’ and cross every ‘t’. This meticulous approach helps catch potential issues before they become full-blown problems, saving time, money, and headaches. In essence, detailing transforms the construction site from a potential chaos zone into a well-oiled machine, churning out top-notch results with the precision of a Swiss watch.

Complexity Management:

Steel detailing is a crucial tool in taming the wild beast of modern architectural design. It’s not just about drawing pretty pictures; it’s about wrangling those mind-bending, gravity-defying structures into something that won’t collapse like a house of cards. Let’s face it, today’s architects love to push the envelope, creating buildings that look like they’ve been beamed down from some alien civilization.

Steel detailing steps in as the voice of reason, translating these ambitious visions into nuts-and-bolts reality. When you’ve got connections more intricate than a spider’s web on steroids, steel detailing is your best friend. It breaks down those head-scratching designs into manageable bits, ensuring that every beam, bolt, and bracket knows exactly where it needs to go. It’s like having a hyper-detailed roadmap for construction crews, preventing them from getting lost in a labyrinth of steel and concrete. In essence, steel detailing is the unsung hero that keeps modern architecture from becoming a beautiful but impractical mess. It’s the difference between a stunning skyscraper and an expensive pile of scrap metal. So next time you see a building that looks like it’s defying the laws of physics, thank a steel detailer for making sure it actually stands up.

Prefabrication:

Accurate detailing is a game-changer when it comes to off-site fabrication, and let me tell you, it can work wonders for on-site assembly speed. Picture this: instead of a chaotic construction site with workers scrambling to put everything together from scratch, you’ve got pre-made components rolling in, ready to be slotted into place like a giant, real-world puzzle. It’s not just a little faster – we’re talking about potentially slashing assembly time in half or more. This approach isn’t just about speed, though. It’s about precision, too. When you’re fabricating off-site, you’re working in a controlled environment. No rain, no wind, no unexpected hiccups.

his means each component can be crafted to exact specifications, fitting together seamlessly when they arrive on-site. It’s like the difference between trying to build a house of cards in a windstorm versus in your living room – one’s a recipe for frustration, the other’s a smooth operation. And let’s not forget the ripple effects. Faster assembly means less time on-site, which translates to lower labor costs, reduced disruption to the surrounding area, and a quicker return on investment. It’s a win-win-win situation that’s revolutionizing the construction industry. So yeah, accurate detailing for prefabrication? It’s not just a nice-to-have – it’s a total game-changer.

Clash Detection:

This powerful feature is a game-changer in the construction industry, helping to identify and resolve potential conflicts between different building systems before the first shovel hits the ground. It’s like having a crystal ball that shows you where pipes might collide with beams or where electrical conduits could interfere with HVAC ducts. By catching these issues early in the design phase, clash detection saves a ton of headaches, time, and money that would otherwise be spent fixing problems on-site.

It’s not just about avoiding embarrassing mistakes; it’s about streamlining the entire construction process and ensuring that everything fits together like a well-oiled machine. This proactive approach to problem-solving can significantly reduce change orders, delays, and cost overruns, making projects run smoother and more efficiently from start to finish.

Future Maintenance:

Detailed drawings serve as invaluable references for future renovations or maintenance work, acting as a time capsule of your home’s inner workings. These meticulously crafted blueprints aren’t just pretty pictures; they’re your home’s user manual on steroids. When that pesky pipe starts leaking at 2 AM or you suddenly decide your living room needs a facelift, these drawings will be your saving grace. They’ll save you from turning your walls into Swiss cheese while hunting for electrical wires or plumbing. Plus, they’ll help prevent those “oops, I didn’t know that load-bearing wall was there” moments that can turn a simple reno into a structural nightmare. In essence, these drawings are like a crystal ball for your home, helping you foresee and navigate potential issues before they become wallet-draining disasters.

In today’s breakneck construction world, steel structural detailing isn’t just important—it’s downright crucial. Let’s face it, this meticulous process is the unsung hero, the real backbone of our modern building practices. It’s what keeps our structures efficient, safe, and pushing the envelope of innovation. Think about it: whether you’re slapping together a modest home or erecting a sky-scraping behemoth, high-quality steel detailing services are your secret weapon. In an industry where time is money and mistakes can cost millions, investing in stellar steel detailing is a no-brainer. It’s the smart move that keeps projects on track, budgets in check, and safety standards sky-high.

2 thoughts on “Importance of Steel Structural Detailing in Modern Construction Marvels”